BATT™ LAP Resurfacing Service

Things happen!

Accidental gouges, contamination with the wrong grit, in one case, bad cooling water with sand in it, and in another, a worn-out prepolish lap had thrown loose diamond all around the machine!

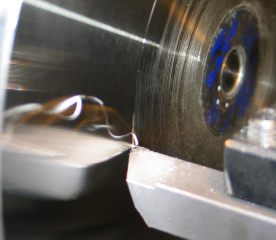

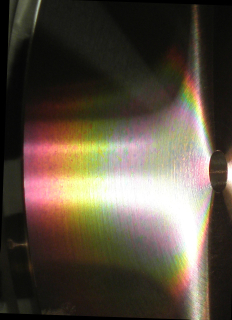

Look at that finish on a beat-up old lap!

BATT™ Laps, as with any other polishing lap, are intended for maximum diamond retention...So naturally, if a contamination accident happens, they will "do their job", and retain the contaminant!

This is where the advantage of a solid cast lap shows up! Rather than discarding them, they can simply be resurfaced, many times. I have had people return laps for resufacing after ten years of use. They end up with what is essentially a "New" lap, just .040-080" thinner. If the lap is more than five years old, it will actually be returned with a better finish than when it was new, because I switched to diamond turning tools a few years ago.

Thus, the BATT™ lap probably has the lowest cost-per-year than any lap on the Market.

Send the damaged lap, with $44.00 (This will INCLUDE return shipping to you!) and I will try to turn it around quickly.

Email me in advance so I can schedule a resurfacing session, and give you a shipping address and maybe I will be able to do more than one at once.

If I can, it removes the expense of setup for second or third laps. Any lap after the first lap is only $20.00

(The lathe and Miller are usally set up for something else, and need to be broken down and set up for the resurfacings.)

A few months ago, someone showed up with a SUITCASE full of them. He's no fool!

OTHER LAPS: Yes, I will resurface other metal or polymeric laps...It uses the same tooling,and the labor is the same.

Some old copper laps will have to be taken on a "Best Effort" basis, though. Some of the older alloys have been serious problems.

NOTE: Sorry, NO LEAD or Lead/Tin solder laps. I manufacture lead-free products here. The penalties for improper lead disposal are too severe to take that chance.

NOTE: LAPS THAT HAVE BEEN DROPPED ONTO A HARD SURFACE USUALLY HAVE GRAIN DAMAGE AT THE EDGE SO SEVERE THAT RESURFACING IS DOUBTFUL!

BATT™ is designed to be a work-hardening alloy, so that it wears well and entraps diamonds.

I have also had a few returned in this condition under my (generous) warranty. I am proud of the title of my warranty page, but this has to start working in both directions, to be fair.

New Charging Video

Here is a movie clip of the new EASY charging process. I started with a piece of CZ (Since a few people think it is hard to polish).

This CZ was sawn, and then ground to a #600 finish.

The camera original runtime was 1:45 seconds.

Yes, 1:45 seconds to charge the new lap and 3K prepolish a piece of CZ. I edited it down to the essentials so it is only about 3Megs.