WARRANTY AND CUSTOMER SUPPORT POLICY

That's right! No disclaimers and no Weasle Words!

The BATT Lap probably has the lowest return rate in the industry, at far less than 1%!

With this degree of customer satisfaction, I have always been happy to work with new BATT users, to make certain they have good results with the BATT lap..After all, I am a gemcutter myself, and take pride in my products! Remember, I orginally developed the BATT lap for my own shop.

Most returns have been for shipping damage, or accidents. For example, one person ran over one with a chair, another had a visiting grandchild drop one on the floor, a few people have gotten theirs contaminated with things like a well that delivered sandy cooling water, or a 1200 lap that was dying and throwing contaminants around.

In these cases, the lap is instantly replaced for the tokenresurfacing fee.

In rare cases of casting or machining defects , the lap is immediately replaced with no shipping charge on the replacement. Just send me the questionable one so I can throw it in the melting pot! (It is an expensive alloy.)

Pretty simple and straightforward!

Having trouble getting used to the lap? Never used charged metal laps before?

E-Mail me!

I am always glad to work with new users, whether a beginner, or a long-time "Other lap" user!

I am proud of the many people I have been able to help "convert" to the BATT lap!

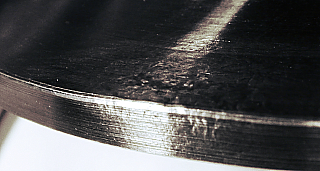

NOTE: LAPS THAT HAVE BEEN DROPPED ONTO A HARD SURFACE USUALLY HAVE GRAIN DAMAGE AT THE EDGE SO SEVERE THAT RESURFACING IS DOUBTFUL!

I have also had a few returned in this condition under my (generous) warranty. I am proud of the title of my warranty page, but this has to start working in both directions, to be fair. Since BATT™ rings like a bell, unless it happened in shipping (And this causes carton damage or crushing), most people are aware of it when they drop the lap on the floor.

Here is a returned "Defective" lap.:

Back to the BATT page.

__________________________________________________

QUESTIONS? E-MAIL ME !