BEWARE OF BARGAINS with DIAMOND POWDER!

Once in a while, a customer writes that their BATT lap is "Scratching".

Usually, this is caused by contamination, overcharging, dust in the cooling water, or a dying #1200 or coarser lap that is throwing loose diamond particles around.

Recently, however, there have been some diamond powder "Great Deals" that have contributed to the misery of my users, and of course, myself.

For many decades, diamond powders were usually selling for $2.00 a carat. In the last two years, prices have dropped to around $0.50 a carat.

With the decline of the Former Soviet Union, many cash-strapped countries have been having "clearance sales", and generally, this can be a good thing for everyone. We get good products, they get hard cash, and everyone is happy.

But as with most things, there is no "Free Lunch". As usual, if an offering sounds too good to be true, it usually is!

I just resurfaced a BATT lap for someone who had a scratching problem; He sent me a small vial of the alleged 50,000 grit diamond he used to charge and polish.

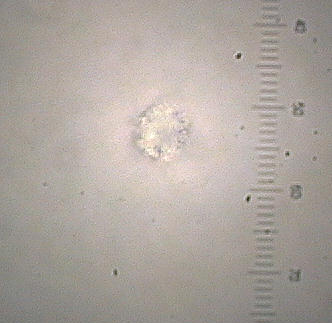

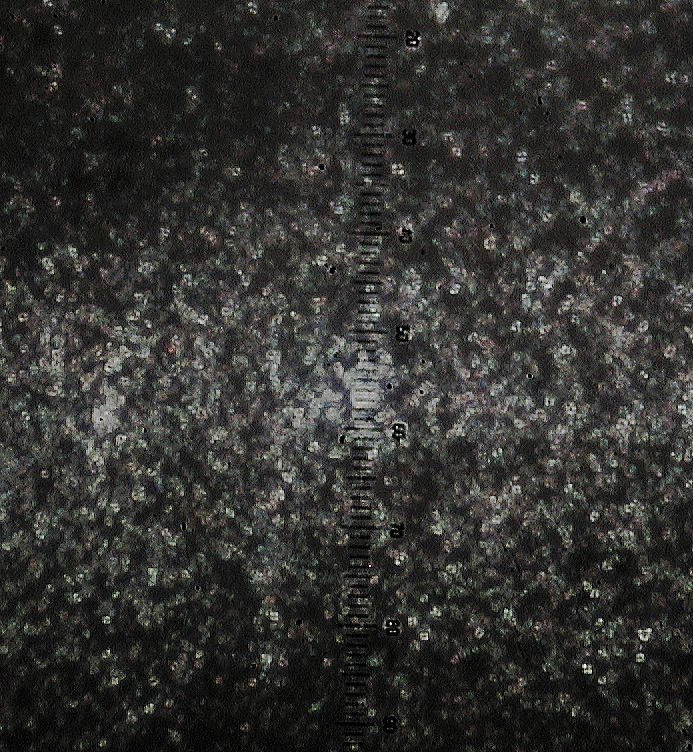

The photomicrographs below were taken at 400X with polarized light of an oil dispersion of the submitted sample. The average particle size for 50,000 Mesh should be 1/2 micron at the 68th percentile of the Gaussian Distribution Curve. At 400x, this is at the very edge of the diffraction limit of my Unitron metallographic objective, so the bulk of the powder in the oil dispersion should not be readily resolved.

In the pictures below, particles of 2 microns and greater are easily visible. (8-14,000 grit.)(The reticle in the pictures is not calibrated for the 40X objective.)